Industrial IoT PCB Assembly Europe plays a crucial role in modernizing industries. It involves creating specialized circuit boards designed for the Internet of Things, enabling machines to communicate, collect data, and perform tasks autonomously. These advanced boards are widely utilized in factories, energy systems, and healthcare applications.

Across Europe, Industrial IoT PCB assembly drives innovation and strengthens industries. It empowers businesses to adopt smart technologies while promoting sustainability. This technology is a key contributor to Europe’s digital transformation and economic growth.

Key Takeaways

Industrial IoT PCB assembly helps machines talk and work alone. This boosts efficiency in industries across Europe.

IoT PCBs are strong, dependable, and save energy. These features make them important for modern factories and automation.

In healthcare, IoT PCBs improve medical tools. They help monitor patients better and make quicker decisions.

The car industry uses IoT PCBs to make vehicles safer and more efficient. They are especially useful in electric and self-driving cars.

Even with high costs and cybersecurity problems, IoT PCB assembly has big growth chances in Europe, especially in major industries.

What Is Industrial IoT PCB Assembly?

Definition and Core Components

Industrial IoT PCB assembly means making special circuit boards for IoT. These boards are used in factories and other industrial places. They help devices connect, share data, and work better.

The main parts of these boards are:

Microcontrollers and Processors: These are like the brain, controlling tasks and data.

Sensors: They gather information like heat, pressure, or movement.

Communication Modules: These let devices send and get data wirelessly, using Wi-Fi or Bluetooth.

Power Management Systems: They save energy and keep the device running smoothly.

Printed electronics help make these boards light, bendable, and affordable for many uses.

How It Works

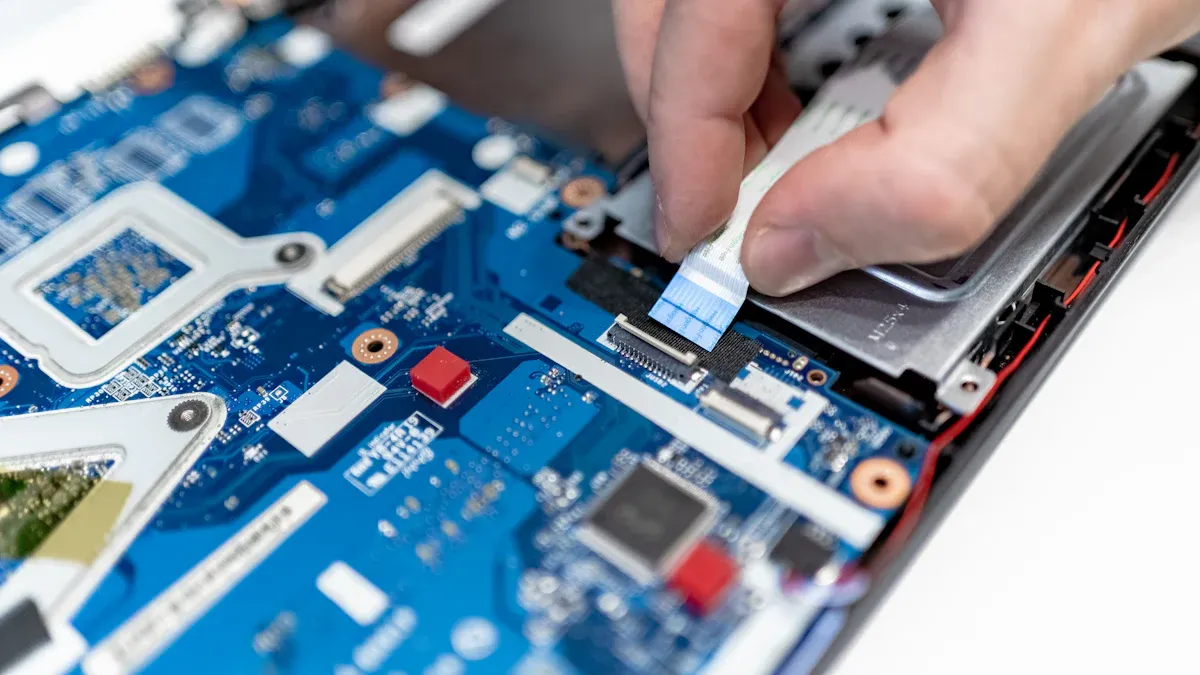

First, engineers design the board, deciding where parts will go. They also plan how electricity will flow through it.

Next, factories build the boards using advanced tools like SMT. After making them, they test the boards to ensure they work well.

When used, these boards help IoT devices run smoothly. For example, in a factory, sensors collect machine data. The microcontroller processes this and sends it to a system. This helps monitor machines and make smart choices.

Key Features for Industrial Applications

Industrial IoT PCBs are made for tough work environments. Their important features include:

Durability: They can handle heat, vibrations, and chemicals.

High Reliability: They work consistently to keep production running.

Scalability: They can be adjusted for small or big operations.

Energy Efficiency: They use less power, helping save energy.

Connectivity: They connect easily with other IoT systems and devices.

These features make industrial IoT PCB assembly in Europe a leader in improving industries and making them smarter.

Applications of Industrial IoT PCB Assembly in Europe

Manufacturing and Automation

Industrial IoT PCBs are important for today’s factories. These boards link machines, sensors, and systems to work together. Factories can track machine health and predict repairs early. This reduces delays and keeps production steady.

These boards are light and flexible, perfect for robots. For example, robotic arms with sensors can move based on live data. This makes them more accurate and cuts down on wasted materials. Using Industrial IoT PCBs turns old factories into smart, automated ones.

Energy and Utilities

Energy systems in Europe gain a lot from IoT PCBs. These boards help track and manage energy use instantly. Sensors in power grids find problems and improve energy flow. This lowers costs and keeps services reliable.

Printed electronics also help renewable energy projects. For example, solar panels with IoT boards can follow sunlight better. This boosts energy output and helps the environment. IoT PCBs make energy systems smarter and more eco-friendly.

Smart Cities and Infrastructure

Smart cities depend on IoT PCBs for connected systems. These boards help manage traffic, check air quality, and improve services. Sensors in roads and bridges find damage early, making repairs faster and safer.

These boards are bendable and easy to use in cities. For instance, streetlights with sensors can dim when no one’s around. This saves energy and improves city life. By using IoT PCBs, European cities can become smarter and more efficient.

Healthcare and Medical Devices

Industrial IoT PCBs have changed healthcare by improving medical devices. These special circuit boards are used in many ways. They are found in wearable health gadgets and advanced diagnostic tools. They collect, process, and send patient data quickly. This helps doctors make better decisions and give better care.

For example, fitness trackers and heart monitors use IoT PCBs. These devices gather health data and send it to doctors. This allows doctors to check on patients without hospital visits. It also helps them act fast when needed. In hospitals, machines like MRI scanners use IoT PCBs. These boards help create clear images and accurate results.

IoT PCBs are also used in surgical robots. They control robotic arms, helping surgeons do precise surgeries. Hospital systems also use these boards to work better. They track tools, manage supplies, and save energy in hospitals.

Healthcare IoT PCBs must be strong and reliable. They can handle cleaning and work well in tough conditions. They also save energy, so devices like pacemakers last longer without new batteries.

By using IoT PCBs, Europe’s healthcare is becoming smarter and more connected. These changes improve patient care and make healthcare easier and greener.

Automotive and Transportation

The car and transport industries in Europe use IoT PCBs a lot. These boards make vehicles safer and work better. They are used in electric cars, self-driving cars, and smart traffic systems. IoT PCBs let cars and systems share data in real time. This makes travel safer and faster.

In electric cars, IoT PCBs manage batteries and energy use. They help cars run well and keep batteries lasting longer. Self-driving cars use these boards to read data from sensors and cameras. This helps them drive safely. IoT PCBs also power systems like lane-keeping and crash prevention.

Smart traffic systems use IoT PCBs to control traffic and stop jams. Sensors in roads and lights talk to cars to find the best routes. Public transport also uses these boards to manage buses and trains better. This improves travel for passengers.

The need for IoT PCBs in cars is growing fast. Reports show the market will grow a lot soon:

Year | CAGR (%) | Key Growth Factors | |

|---|---|---|---|

2024 | 2.59 | N/A | Demand for high-powered electronics, automotive electronics growth |

2025 | 2.85 | 9.8 | Telecommunications infrastructure, consumer electronics growth |

2029 | 4.10 | 9.5 | Popularity of electric cars, IoT proliferation, energy-efficient electronics |

This growth shows how important IoT PCBs are for cars. By using these boards, Europe is building smarter and greener transport systems.

Benefits and Challenges of Industrial IoT PCB Assembly in Europe

Benefits: Efficiency, Innovation, and Sustainability

Industrial IoT PCBs bring many benefits to European industries. A big advantage is better efficiency. These smart boards help machines share data easily. This reduces delays and improves production. For example, sensors on these boards check machines and predict repairs. This keeps everything running smoothly with fewer problems.

Another benefit is innovation. Adding IoT to systems creates smarter technologies. These systems can study data instantly and help make quick decisions. This leads to new ideas and growth in areas like factories, healthcare, and transport.

Sustainability is also important. IoT PCBs use less energy, which helps the environment. Solar panels with these boards work better and make more energy. Using this technology supports a greener and cleaner future.

Challenges: Costs, Regulations, and Cybersecurity

Even with benefits, there are challenges for IoT PCBs in Europe. High costs can be a problem, especially for smaller companies. Building factories and buying advanced tools costs a lot of money. Rules and regulations also make things harder. Following strict policies takes time and adds expenses.

Supply chain issues are another challenge. Shortages of materials and delivery problems raise costs. These delays can slow down production and hurt efficiency.

Cybersecurity is a big concern too. More connected devices mean more chances for cyberattacks. Protecting data and keeping systems safe needs strong security plans. Companies must spend on security to avoid risks.

Solving these problems can unlock IoT PCB’s full potential in Europe. Working together, planning smartly, and being creative are key to overcoming these challenges.

The Future of Industrial IoT PCB Assembly in Europe

Emerging Trends and Innovations

Industrial IoT PCB assembly is seeing exciting new changes. People want faster and better electronic devices. This is pushing new ways to build circuit boards. For example, system-in-package (SiP) and 3D stacking are now important. These methods help meet the needs of 5G and IoT for speed and connection. The Embedded Package Substrates market is also growing fast. This shows how important advanced designs are for quicker data and better connections.

Another big change is adding artificial intelligence (AI) to IoT systems. AI-powered PCBs can make decisions quickly and predict problems. This helps save time and makes work more efficient. Flexible and printed electronics are also becoming popular. These make devices lighter, easier to use, and cheaper. By learning about these trends, you can see how Industrial IoT PCB assembly is shaping the future.

Growth Potential in Key Industries

Industrial IoT PCB assembly has a lot of room to grow in Europe. The semiconductor industry is expected to grow by 12.6% by 2025. Chips for electric and self-driving cars may grow by 11.8% yearly from 2024 to 2028. AI chips, used in smart devices, could grow by 33% by 2025.

Industry | Growth Rate | Timeframe |

|---|---|---|

Semiconductors | 12.6% | 2025 |

Automotive Chips | 11.8% (CAGR) | 2024 to 2028 |

AI Chips | 33% | 2025 |

These numbers show industries are using IoT technologies more. By focusing on these areas, you can see how Industrial IoT PCB assembly will grow and change industries.

Role in Europe’s Digital Transformation

Industrial IoT PCB assembly is helping Europe become more digital. It lets industries use smart technologies and improve their work. For example, IoT PCBs help factories automate tasks and check machines in real time. This boosts productivity and cuts waste.

These technologies also help Europe’s green goals. IoT PCBs make solar panels and other renewable energy systems work better. They also help cities become smarter with connected systems. By using these advancements, Europe can become more innovative and eco-friendly.

Industrial IoT PCB assembly is key to Europe’s industrial future. It helps industries use smart tech, work better, and protect nature. By using this technology, industries grow and become more eco-friendly. It benefits areas like factories, healthcare, and transport.

To make the most of it, teamwork and funding are needed. Supporting progress means working together and solving issues like high costs and data safety. These actions will help Europe stay strong in innovation and digital growth.

FAQ

What does Industrial IoT PCB assembly do in smart factories?

Industrial IoT PCBs link machines, sensors, and systems in factories. They help check equipment, plan repairs, and automate work. This makes factories run better and have fewer delays. Using these PCBs helps factories become smarter and eco-friendly.

How do IoT PCBs help renewable energy?

IoT PCBs make solar panels and wind turbines work better. They watch how they perform and adjust for best results. For example, solar panels with IoT PCBs follow the sun more closely. This makes more energy and helps the planet. 🌱

Are IoT PCBs protected from hackers?

IoT PCBs can face hacking risks because they connect online. To stay safe, companies use tools like encryption and firewalls. They also update systems often to block threats. Good security keeps data safe and stops hackers.

Why are IoT PCBs useful in healthcare?

IoT PCBs power devices like heart monitors and surgery robots. They collect and send patient data quickly, helping doctors act faster. These boards also help hospitals track tools and supplies. This makes healthcare smarter and more organized.

Which industries gain the most from IoT PCBs?

Industries like factories, energy, healthcare, and transport benefit a lot. IoT PCBs improve machines, save energy, and connect devices. For example, they help factories run smoothly and make cars safer. These boards bring new ideas to many industries. 🚀